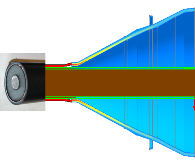

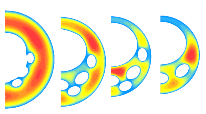

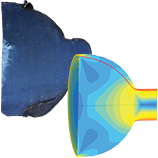

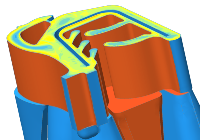

We offer full CAE analysis and design services for any extrusion processing application. From extrusion screw and die design to co-extrusion analysis, we can provide you with the engineering services you need to get the job done right the first time.

Contact us, at your convenience, to discuss your upcoming project/problem with our polymer processing experts.