The COMPUPLAST® VEL™, Flat Die module™ is used for the analysis and design of the types of dies that are typically used in flat film and sheet production or extrusion coating applications.

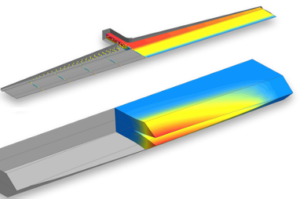

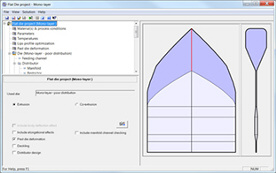

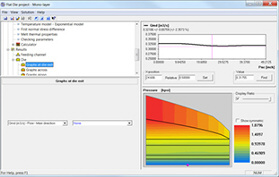

Using the fast, Control Volume Method (CVM) of mathematical analysis, or a fully 3D Finite Element Method (FEM), this module can provide the user with an accurate prediction of the expected die performance. From simple “T-Slot” dies to complex “Coat-hanger” designs, the Flat Die module has the versatility to accommodate almost anything a designer can come up with. The “Coex” option can be used to simulate a “Feed-Block” type of coextrusion of up to 5 layers. The user-friendly, intuitive interface and CVM solution technique allows the user to optimize designs quickly and easily.

The VEL™, Flat Die module has been developed with the extrusion process engineer in mind. Many world class extrusion die manufacturers use the VEL™ Flat Die module as a part of their daily design procedures. Many processors and technical service personnel use this module to study and analyze the effect of resin changes on their process.

In addition to flat dies, this module has also been successfully applied to the design of primary distributors for wide profile dies. In fact, any extrusion application requiring a controlled material distribution can benefit from the Flat Die module. Combine it with the Multi-Layer module and you have all the tools you need to analysis and design coextrusion dies for a wide range of applications.